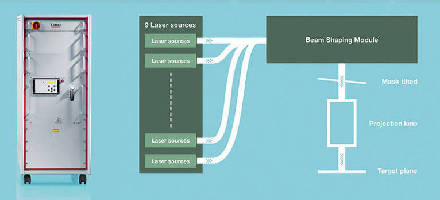

In a positive sense too clever by half is an innovation by LIMO: the company from Dortmund has developed a beam shaping module for its L³ LIMO Line Laser system, which accelerates the annealing processes significantly. Nine fiber-coupled laser modules produce – thanks to the patented beam shaping- a homogeneous, very intense line.

"It must be a linear source which scans over the surface and thus enables a uniform and continuous processing of the irradiated areas." This, Dirk Hauschild, Director Thin-film Activation in LIMO, learned from material specialists from around the world on the question of the ideal energy source for the uniform planar heating of thin films. On the basis of this information the L³ LIMO Line Laser systems have been developed - as an alternative to typical punctual working lasers - e.g. existing of nine fiber-coupled laser modules. In combination with a LIMO Beam Shaping module they produce a homogeneous line (80mm x 0.2mm, inhomogeneity <2.5%) with a very high intensity (10kW/cm ²). The laser beam can directly irradiate the object or be displayed onto the target plane via a projection lens.

Thanks to intensive and uniform irradiation the L³ LIMO Line Laser System - specially developed for continuous use - is qualified for many industries: from the automotive, electronics, coating industry and the manufacturing of energy storage units to photovoltaic and display technology. The patented LIMO beam shaping guaranties a continuous 24/7 use. The laser beam and the relevant process parameters are stabilized even in the case of failure of individual laser sources.

The system may be considered for:

• Short-term tempering: modifying surfaces and coatings through extremely fast heating

• Selective tempering: selective heating of certain surface materials

• Rapid thermal annealing: annealing of crystal defects within milliseconds

• Laser-induced thermal printing (LITI)

• Rapid thermal processing: produce a new material or new material characteristics from two deposited materials

• Drying, cross-linking of paints and polymers

• Integration within in-line and scan or repeat processes possible

The system’s 24/7 continuous operation with high process stability speaks for itself. Additionally, the user can replace individual laser modules without readjustment of the optical components. Moreover, with the failure of one laser module the homogeneity of the line is preserved. The manually or remotely controlled system can be easily integrated within existing production environments due to standardized interfaces.

The system is a very good example for manufacturers of "flat panel displays" that - thanks to the targeted inline laser annealing – makes a variety of chemical processes superfluous and so simplifies production significantly.

The Applications Center of LIMO gladly develops other processes and applications together with interested companies. |